Injector leak-off arrangements - spill lines (also known as spill rails and spill racks)

What is a spill line?

The diesel fuel injector's role is to inject an atomised, spray of fuel into the engine. Its components include a spring-loaded needle that opens and closes rapidly allowing fuel to flow through the injector nozzle holes. Lubrication is crucial to this action and this is provided by a tiny amount of fuel that 'leaks' back past the needle into the body of the injector. This 'leaked' fuel finally leaves through a connector of various designs, depending on the manufacturer, to the spill line that returns the fuel to the tank or the fuel system.

The old BSS requirements for spill lines were that they had to be either of metallic material or fire resistant hose to at least BS EN ISO 7840. Where hose was used it had to be efficiently attached to injectors with clamped or swaged threaded connectors.

However that option was inconvenient for a small number of engines because available conversions require machining of injector bodies leading to difficulties with warranties, spares availability and cost.

To assist owners of these engines BSS Technical Committee were asked to investigate the risks presented by non-compliant arrangements and potential compliance options not affected by the constraints above.

The current option is that injector leak-off (spill rail) arrangements must meet all the requirements for fuel feed and return pipes, hose and connections, or

- utilise the direct return to tank option, or

- return to the fuel system through a non-return valve.

- injector leak-off hoses fitted by the manufacturer within an enclosure on the engine meet the requirement.

Vintage and traditional engines designed to return the injector leak-off fuel to a catch pot are acceptable provided the catch pot is securely mounted and is free of signs of leaks, signs of damage or deterioration.

Detail

Supported by the evidence of the research, the current compliance options were developed on the basis that only a small amount of fuel flows from the injector leak-off points.

The risk being managed is that of adding fuel to a fire in the event of the heat destroying the generic polymer spill line within two-and-a-half minutes, i.e. the minimum standard of protection in the other parts of the fuel system. Such a rupture would allow diesel in other parts of the fuel system to back-flow and escape from the spill line, thus adding to the intensity of the fire and the associated dangers.

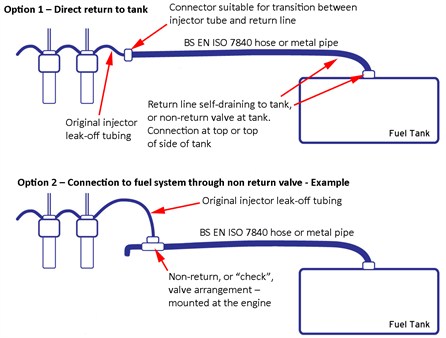

Option one - 'return-to-tank' (see diagram)

This is a straightforward concept where the leak-off fuel is returned directly to the tank through a line of recommended minimum internal diameter 3.2mm. It must self-drain to the tank or enter the tank through a non-return valve. Such an arrangement means there is no connection with any other part of the fuel system (except the tank) and no risk of backflow of fuel in the event of failure. The injector tubing is original equipment but the return line to the tank is ISO 7840 hose (or equivalent) or metallic pipework.

Option two - 'check valve' (see diagram)

This option routes the leak-off fuel through a check valve to a T-branch or junction with the injector pump fuel-return line. The check valve prevents reverse flow and the potential for fuel to be pumped out of a failure point should a rupture happen.

There are now complete proprietary items to fit many engine arrangements. These are often neat options carefully designed to fit the engines taking into account the often awkward angles and challenging spaces.

Photo courtesy of Marine Injector Services

When the NRV option was first announced, a custom non-return or check valve was presented as a possible solution. While the check valve and the T-branch were standard catalogue items from companies such as Delphi and Wade, the connector required some drilling and welding or brazing. (See annotated photograph below). A typical parts list might include:

|

|

reduced_462x651.jpg)